Development of embedded electronics for a mini-rocket (LeoFly – C’Space 2025)

In 2024–2025, I joined LeoFly, the aerospace association of my engineering school, to take part in an ambitious project: the design and construction of a mini-rocket competing in the C’Space, the national event organized by CNES (French Space Agency). Within a team of seven engineering students, I was responsible for the entire embedded electronics and programming.

Project Context and Objectives

The C’Space is the largest European gathering of students passionate about space. Our challenge was to design a mini-rocket capable of fulfilling two critical missions while meeting a strict set of requirements imposed by CNES. The main constraint was that all our electronic systems had to be completely independent, both in terms of power supply and microcontrollers, to ensure safety and redundancy.

System Architecture: Two Independent Subsystems

To meet the requirements, I designed an architecture based on two fully autonomous electronic systems:

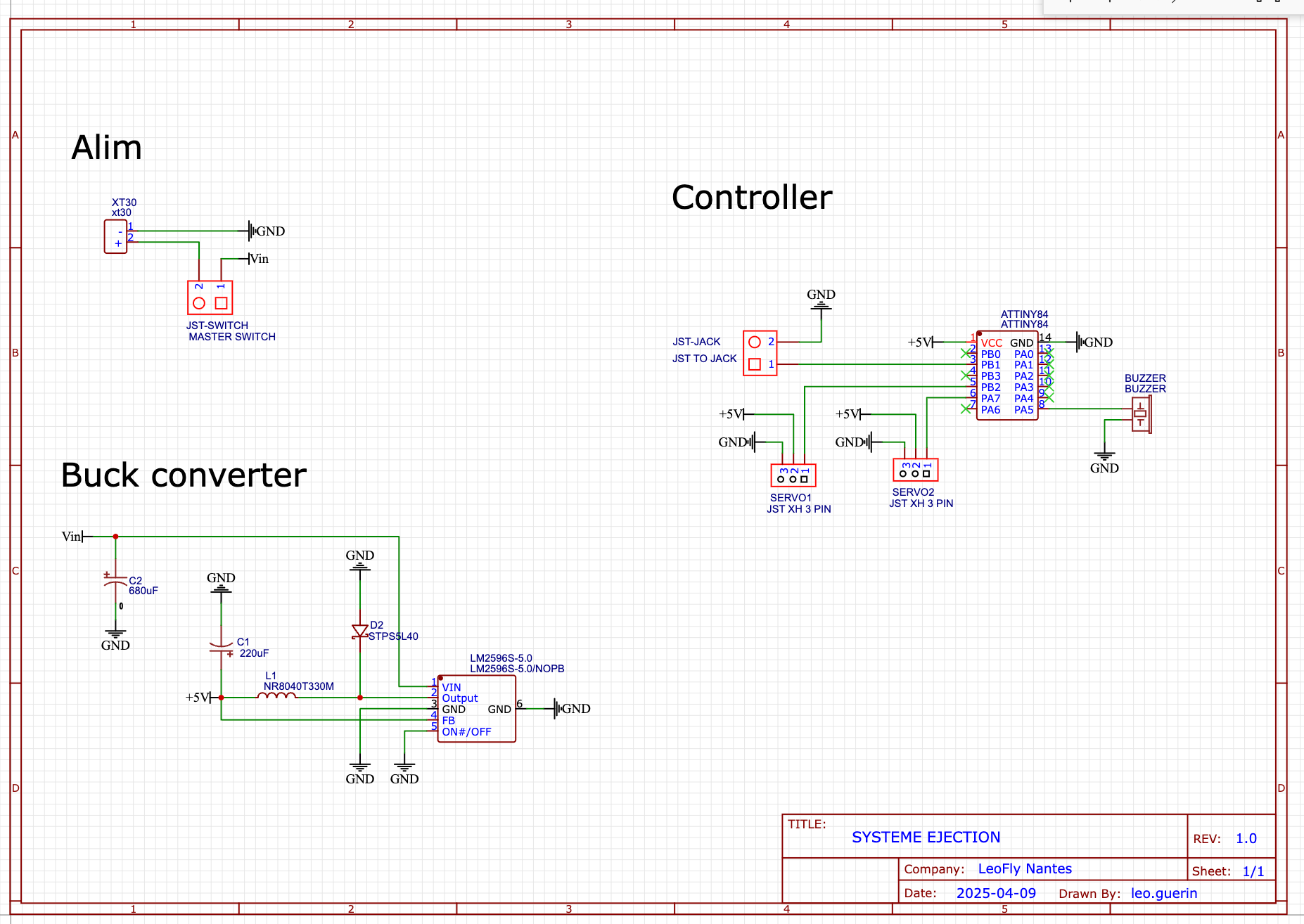

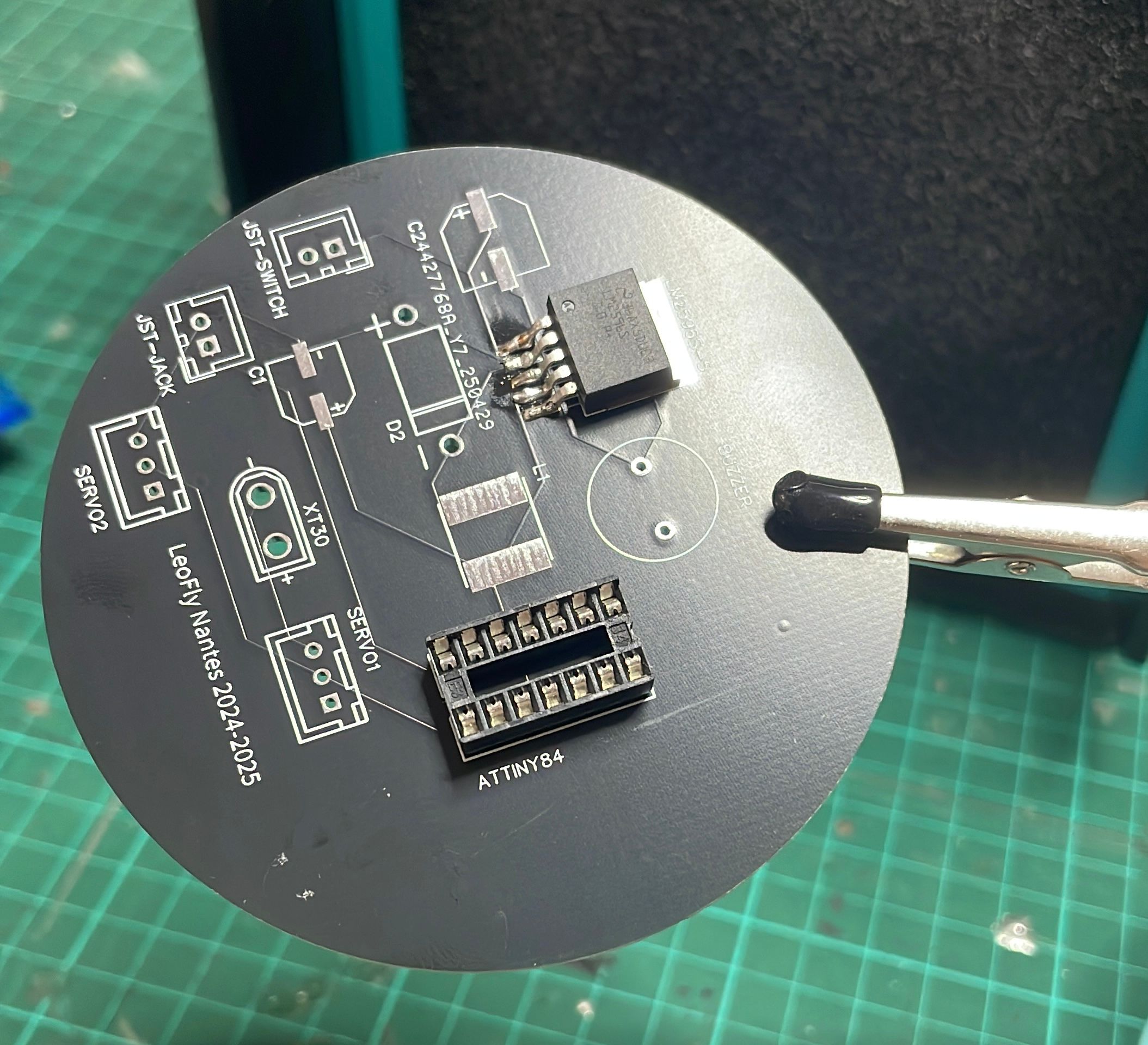

1. Ejection System

The first system forms the core of flight safety. Its role is crucial: to trigger the stage separation at the exact moment calculated by our simulations.

Operating principle:

- At launch, the system remains connected to the ground station via a jack connector.

- At liftoff, the disconnection of the jack automatically triggers a safety timer.

- Once the simulated flight time is reached, a servo motor mechanically activates the separation.

The design already includes scalability, with a second servo motor connector for future experiments on an additional stage.

2. Experimentation System – Telemetry and Data Acquisition

The second system turns our rocket into a real flying laboratory, capable of collecting and transmitting scientific data in real time.

Data collected :

- Altitude: High-precision barometric measurement using a BMP280 sensor

- Kinematics: Velocity, acceleration, and orientation via an LSM9DS1 IMU (9 axes: 3 accelerometers, 3 gyroscopes, 3 magnetometers)

- Telemetry: Real-time transmission to the ground station

Technical Architecture :

- Main board: Arduino MKR WAN 1310 (with native LoRa communication)

- Storage: SD card module for local backup of telemetry

- Integration: Two stacked levels to optimize space

Technical Challenges Overcome

Power Management

The energy autonomy requirement pushed me to optimize every conversion stage. The step-down converters were sized to maintain voltage stability even under the extreme acceleration constraints of the flight.

Long-Range LoRa Communication

Implementing LoRa telemetry was a major challenge. It was necessary to ensure reliable transmission of critical data (altitude, speed, position) to the ground station, even over several kilometers and under vibrational stress.

Compliance with Regulatory Constraints

The CNES specifications impose strict safety rules, particularly the complete independence of systems and the accessibility of controls. Every design choice was validated according to these criteria.

[Photo : Vue d'ensemble des deux systèmes intégrés dans la fusée]

Results and Outlook

This project allowed me to strengthen my skills in :

- Embedded electronics under extreme environmental constraints

- Microcontroller programming (ATtiny84, Arduino MKR)

- Telecommunications (long-range LoRa protocols)

- System integration with mass and space constraints

- Project management within a multidisciplinary team

The modular architecture developed provides a solid foundation for future student space projects. The independent systems not only ensure the level of safety required by CNES but also open up possibilities for evolving toward more complex missions.

Conclusion

Taking part in the LeoFly project for C’Space 2025 was far more than just a technical exercise. It was an opportunity to design electronic systems in a context where every decision directly impacts the safety and success of the mission. This experience strengthened my passion for aerospace and my conviction that precision engineering is the key to meeting the technological challenges of tomorrow.